A Sustainable Cement: Geopolymer

| Research @ Columbia University | 2019 |

As an independent project carried out under the guidance of Professor Shiho Kawashima and Dr. Siwei Ma with Australian colloborator, Dr. Arnaud Castel of UNSW, I did rheology research on a sustainable cement called geopolymer. Sustainable cements are especially pertinent because 7% of global CO2 emissions come from ordinary portland cement production. Quite literally, 1 ton of cement releases 1 ton of CO2.

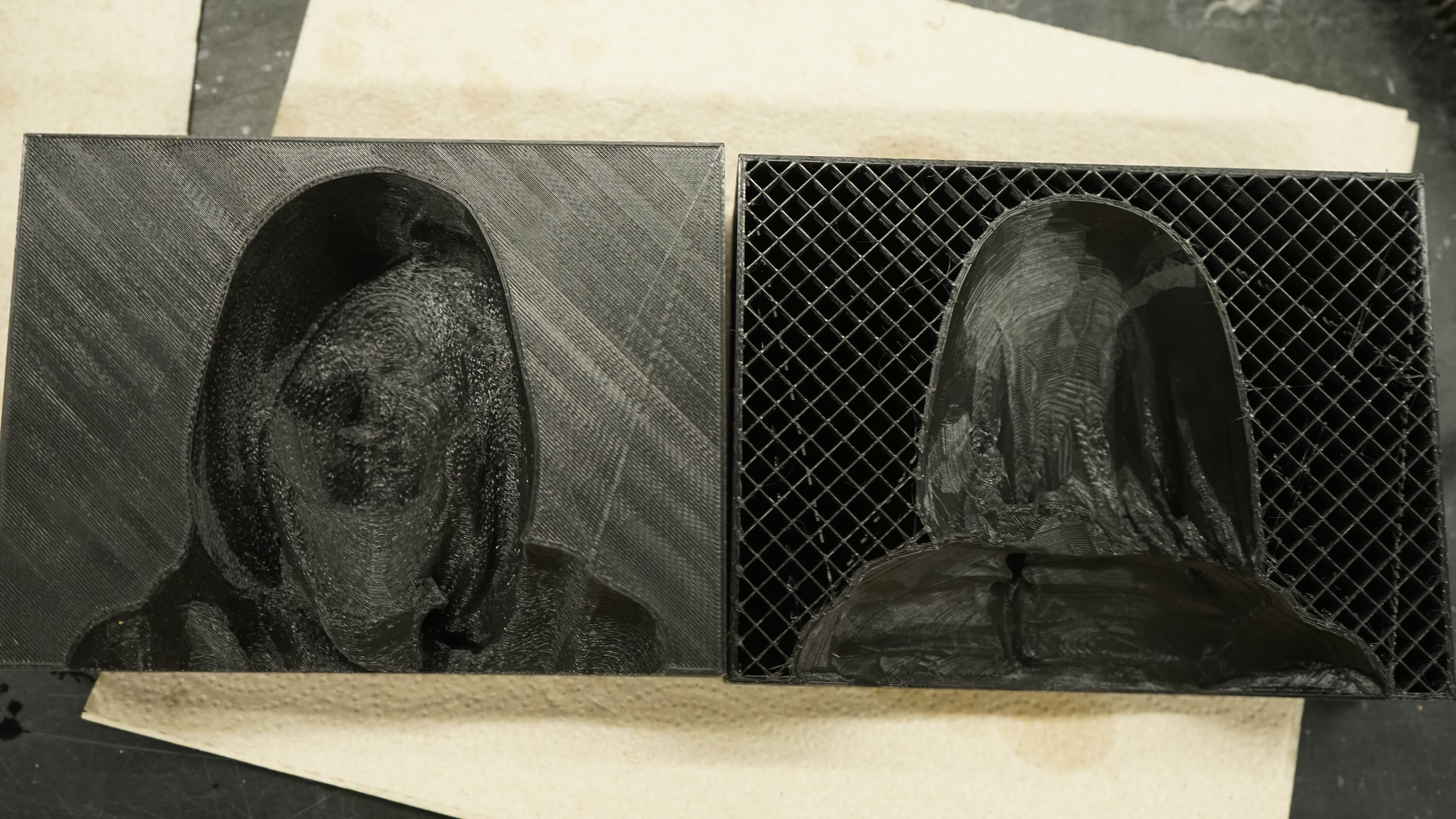

As demos for our senior design expo, I casted busts of Professor Kawashima and Dr. Ma. They double as gifts to them as gratitude for their valuable guidance and support.

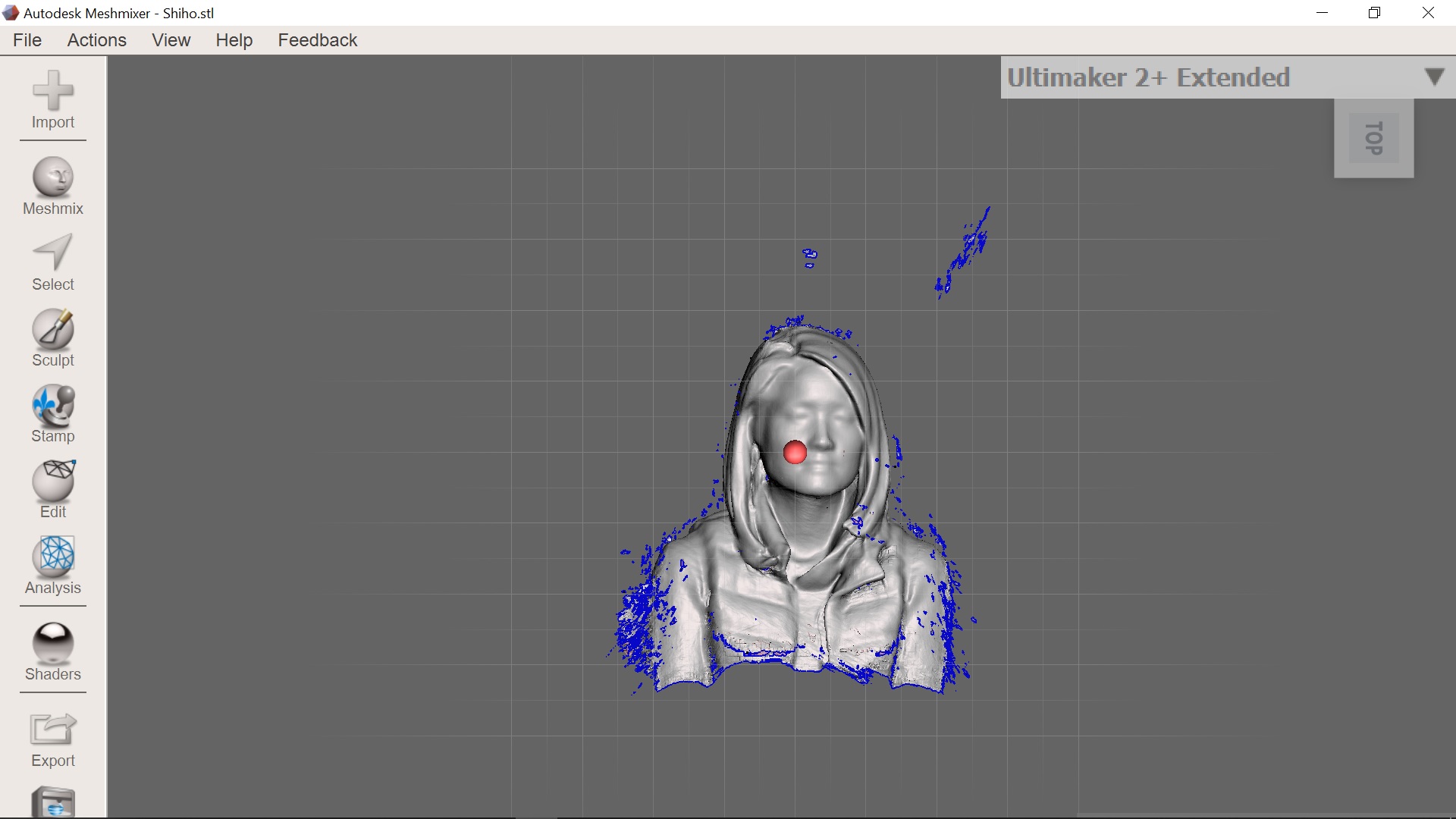

Heads were 3D scanned using Heges and imported in Autodesk Meshmixer for cleanup and editing.

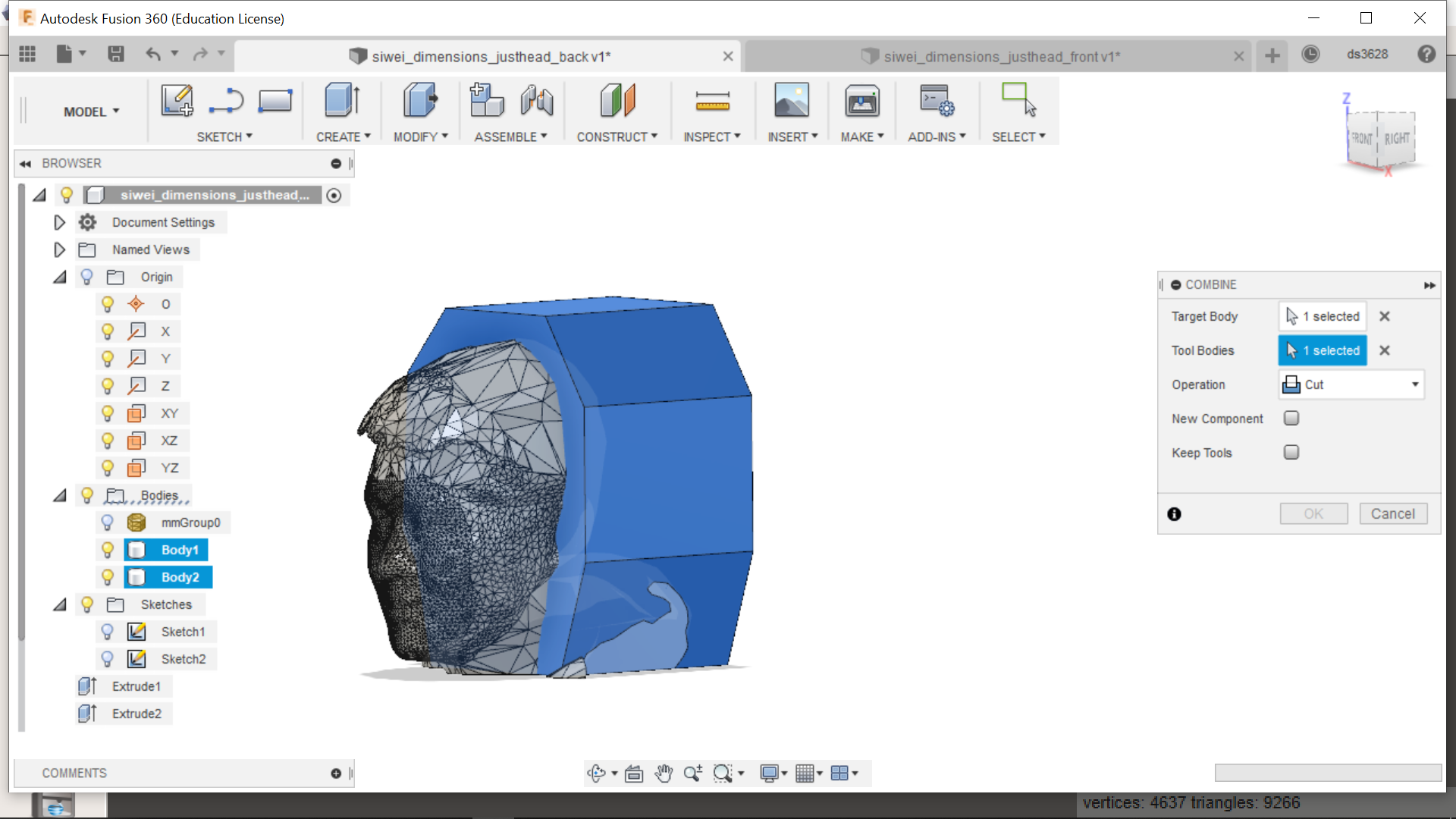

Cleaned model was imported into Fusion360.

A negative was made in Fusion360.

Molds were 3D printed using PLA using Ultimaker Extended 2+.

Prior to casting, molds were machined using a bandsaw to help with demolding. Removed parts were recreated using modeling clay. WD-40 was sprayed for removal ease. Molds were clamped.

A 25% fly ash / 75% slag geopolymer cement was mixed in ASTM mixer, and casted immediately. Cement was let rest in molds for one day.

Due to the rigidity of PLA, a heat gun was used at one point and then further machined and chiseled to remove the molds. Epoxy and modeling clay was used for segments that did not cure properly.

Busts were then water cured for 7 days for strength to develop and to prevent cracking.

The presentation poster for this project can be downloaded here.