Water Distribution System in Ait Bayoud

| Engineers without Borders - Morocco | 2019 |

At engineering school, I focused part of my time designing and successfully implementing a six kilometer water distribution system for two villages, Izgouaren and Ilguiloda, in a rural part of Morocco. These water-scarce villages are the most remote and poor of the series of villages in the Ait Bayoud commune. Residents, primarily women and children, would walk for three to four hours per day to collect water from neighbouring communities and distant springs. Access to a sustainable water supply is vital to the growth and progress of these communities.

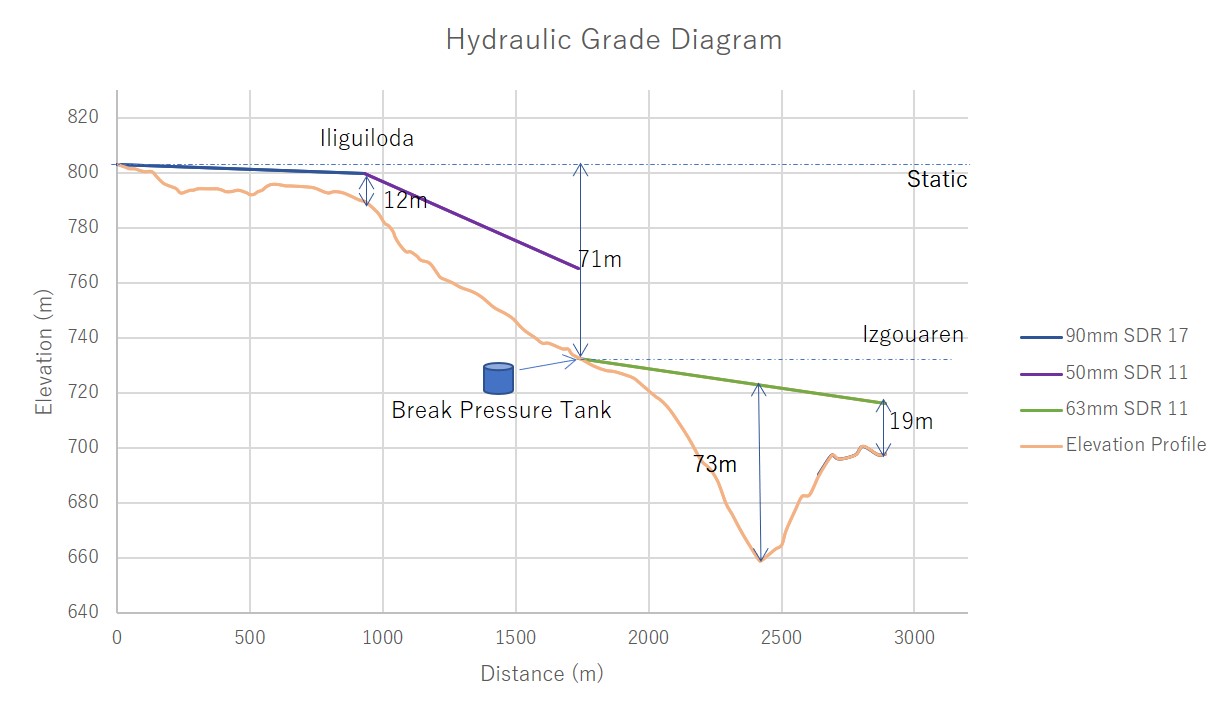

With the industry mentorship of Camille Rubeiz, Santiago Arnalich, and Andrew Wedgner, I drafted my first technical designs of the six kilometer pipeline, half of which is gravity-fed. The most difficult part was teaching myself hydraulics and drawing the hydraulic grade line of the system. The hydraulic grade line diagram tells you if the water will flow to the desired destinations in the pipeline.

On July 16 2019, with over $43,000 of funding in cash and materials that I primarily raised from Borealis, I led the initial implementation team to Morocco. To get a working water distribution system, we needed to build a 38,000 L tank, a solar rack holding 20 solar panels, attach a solar controller to an electric borewell pump, and install six kilometers of PE100 HDPE pipe.

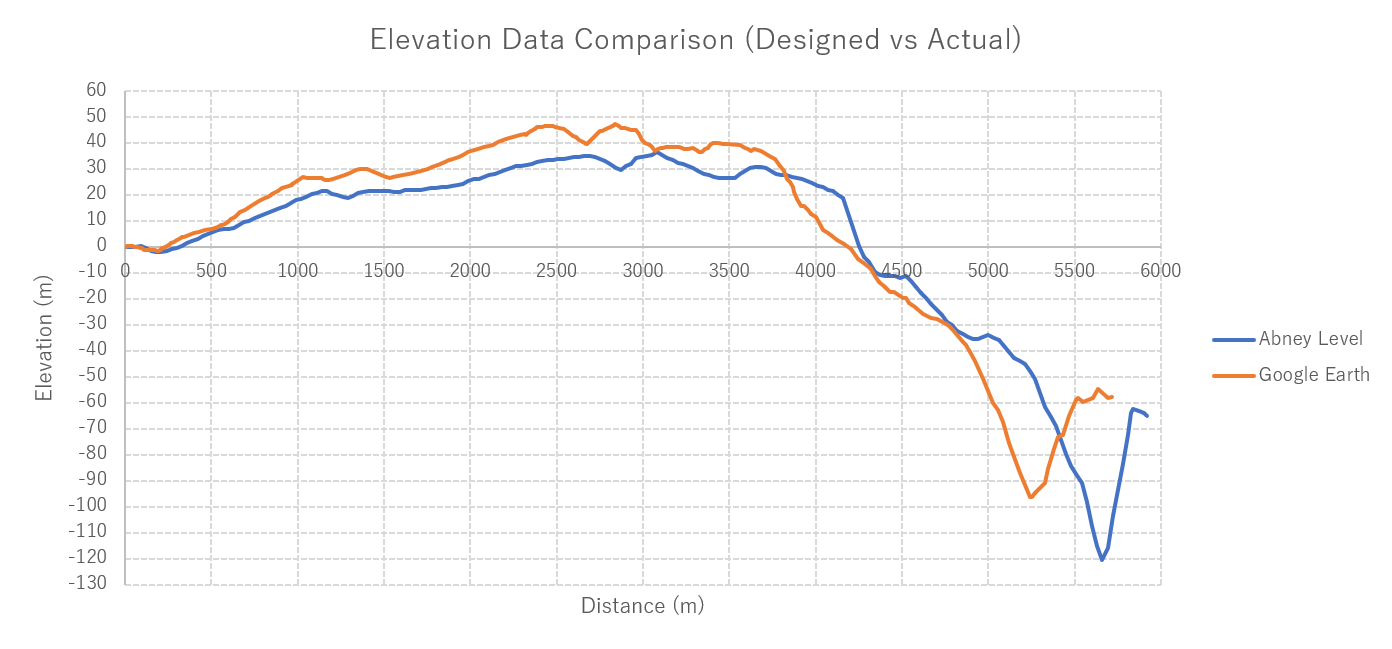

Upon arrival, the first step was to survey the land using an abney hand level.

After reading the manual, I headed into the field and over the course of two weeks, surveyed the entire topography of the pipeline route. The difference between my design on Google Earth was not too drastic!

During the initial weeks, I spent much time establishing trust with the community, figuring out where to source materials, and identifying key leaders in the community. By August, the rest of the implementing team and mentors had arrived. We split the group and for the remainder of the trip, the groups worked in parallel.

Pipe

$18,000 worth of PE100 pipes were extruded in Casablanca and delivered via two cargo trucks through off country dirt roads to Ait Bayoud. Each coil contains 100m of PE100 pipe. After some trial and error, the locals found a system to efficiently unload and uncoil the pipe every 100m along the pipeline route. While they uncoiled, I led a team of locals to fuse the pipe using a McElroy Pitbull 14 machine following ASTM procedures. As the project progressed, I stepped back into an overseer role as the locals took the initiative to learn and participate.

Tank

After two weeks of procuring materials from Marrakech and Casablanca, our team started building the forms for the 38,000 L reinforced concrete tank. Over the course of three intense weeks and in collaboration with the community, the tank was casted and let to cure in water. The tank has two chambers, one of which is a settling tank to deposit sediments in the water and the other acts as a storage tank.

Solar Rack & Pump

After finding out that service for solar pumps was nearly non-existent in Morocco, we decided to switch to using a solar controller for an electric pump. After tank construction was complete, our entire team shifted our efforts to build the solar rack. After installing the panels and connecting the solar controller to the pump, we were near ready to fully test our system.

Moving Forward

In late August of 2019, water reached the first village of Ilguilouda. In six weeks time, we gained the trust of the community and worked with them to construct a 38,000 L reinforced concrete tank, a solar rack holding 20 solar panels, four tapstands, installed a solar controller, and laid four km of PE100 pipe. My role was in designing the entire hydraulic system, raising over $43,000 of sponsorship in cash and materials to carry out the project, and leading in-country implementation from start to finish. Today, life is different for the community of Ilguilouda, and soon for Izgouaren.

Read a detailed log of this journey from planning to implementation here (WIP).

Location

Acknowledgements:

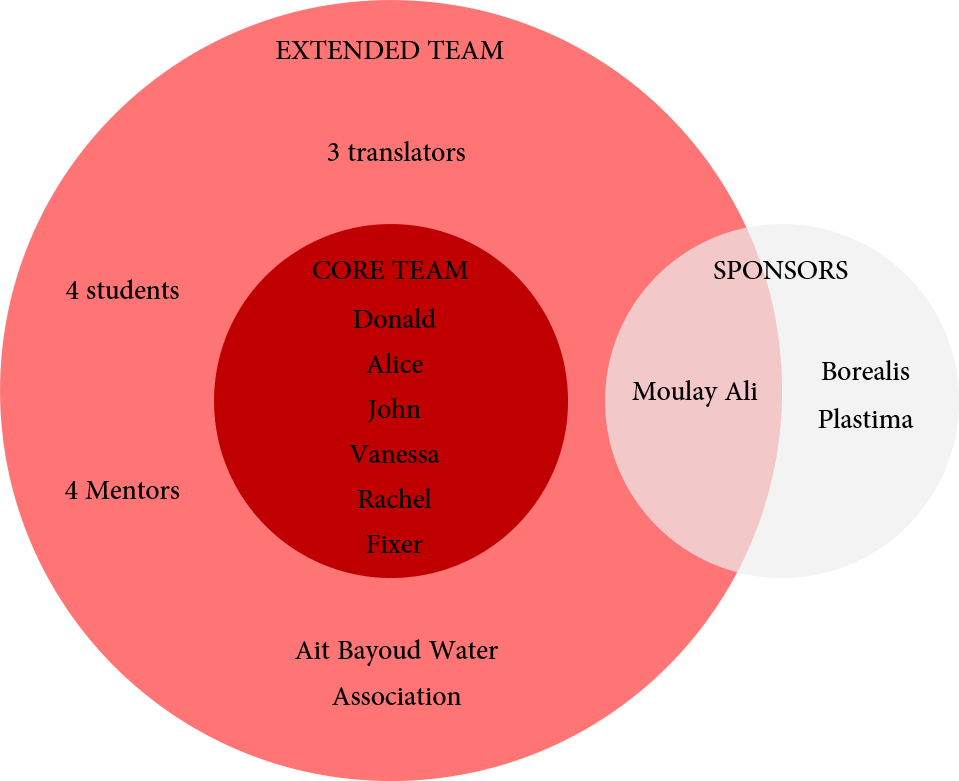

None of this would’ve been possible without the generous mentorship of all the professionals along the way. A huge thanks to my mentors: Robert Lawrence, Camille Rubeiz, Greg Scoby, Santiago Arnalich, and Andrew Wedgner. A thanks to tank and water quality mentors: Michael Conaboy, Sean Reischel, Ethan Cotton, and Robert Prager. A indebted gratitude to our sponsors and supporters: Plastics Pipe Municipal Advisory Board, PE Pipe Alliance, Borealis, Borouge, Plastima, CMGP, Menara Holdings, ISCO (Steve McDonald), and McElroy (Jim Johnston).

Implementing Team:

Last, my rad team who made it all happen in-country. Donald Swen (Piping Lead), Alice Wu (Solar Lead), John Yatsko (Tank Lead), Leanne Pichay (Tapstands Lead), Gabriel McCormick, Raayan Mohtashemi, Justin Paik, Zineb Kouhlel (Translator & Fixer), Zeyneb Ben Chelha (Translator), Meriem Ben Chelha (Translator).

See press on our project: McElroy & Water for the World. See technical documents: drawings, alternatives analysis, pre-trip report, and post-trip report.